Textile Belts

Duo-Ply Belts

Duoply belts are designed to the highest standards with the aim of lowering energy cost of our valued customers. These belts show outstanding strength as to provide the same endurance to elongation and impact as 4-5 ply belts.

Why Derby Duo-Belts

When comparing between duo-ply and multi-ply belts of the same tensile strength (EP) we recommend two layer belts, as they are much lighter in weight. Duo-ply belts give not only weight advantage, but also thickness advantage, which allows for better flexibility on pulley diameter.

Energy Efficiency

As long as the conveyor system is suitable for it, Derby recommends lowering the number of plies to raise the energy efficiency of the plant. Further information on the belt specs and your system’s compatibility can be assisted by our technical team upon your request. These belts are available for all cover grades, including heat resistant, flame resistant, oil resistant, acid resistant and cold resistant.

Advantages Compared to Higher-Ply Belts

• Lower Energy Cost

• Extraordinary Impact Resistance

• Superior Rip, Tear Resistance

• Lighter in Weight : Operational Convenience

• Better Troughability

• Impeccable Load Support

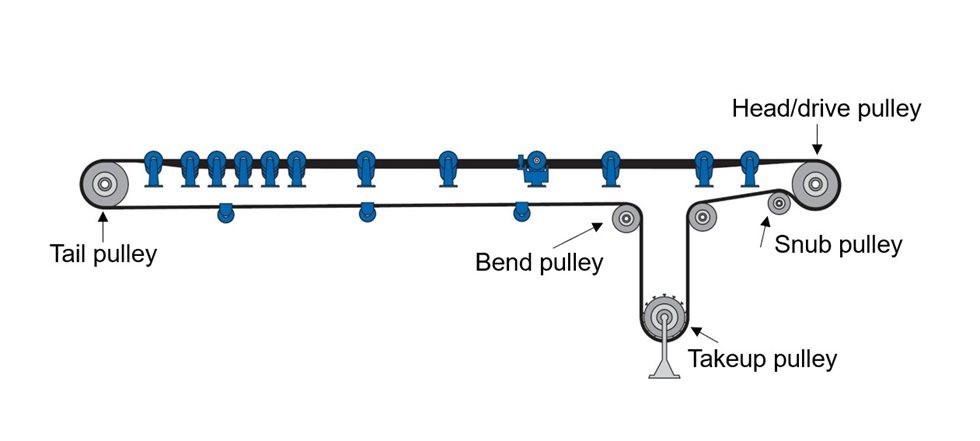

| Belt Type | Min. Pulley Diameter A* | Min. Pulley Diameter B* | Min. Pulley Diameter C* |

|---|---|---|---|

| EP 250/2 | 250 | 200 | 160 |

| EP 315/2 | 250 | 200 | 160 |

| EP 400/2 | 315 | 250 | 200 |

| EP 500/2 | 315 | 250 | 200 |

| EP 630/2 | 400 | 315 | 250 |

| EP 800/2 | 500 | 400 | 315 |

| A: Head/Drive Pulley | B: Tail-Take up Pulley | C: Snub Pulley |